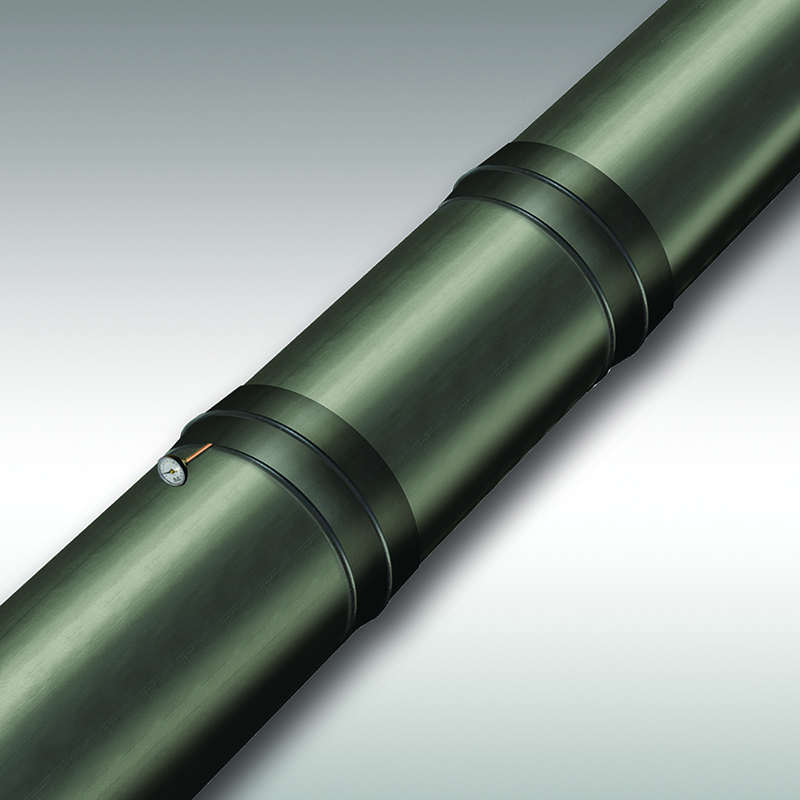

RhinoJoint is Air-Testable, Water-Tight and EN489:2009 Certified, making RhinoJoint the ultimate solution for sealing field joints even under the harshest conditions.

EN489:2009 certification was designed to predict performance over 30 years of operation in the most severe pre-insulated, underground pipeline conditions. Testing parameters for certification include:

- 100 cycles for 24 hours in Sand Box

- Water impermeability test inside pressure vessel with pressurized water for 24 hours

- Optimal protection & sealing of pre-insulated pipeline field joints which maintains the integrity of the piping system

- Will not compromise the system’s ability to minimize heat loss or its moisture resistant properties – seals field joints water-tight!

- No bulging joints; the OD of a RhinoJoint is designed so it aligns with the coating of the main line, minimizing soil stress on the field joint

- Air testing of the field joint is performed without drilling a hole in the outer jacket further maintaining system integrity and saving on hole plugging time

- High thermally-efficient polyisocyanurate half shell foam insulation included in RhinoJoint kit

- Totally shrinkable joint casing system promotes easy installation

- High strength adhesive used on shrink wrap film and end strips ensures adhesion of outer jacket covering and the edge sealing of the RhinoJoint system